Grinding

Grinding works play an important role in the fine machining of plant components, not only during production, but also during repairs and maintenance. With the development of high quality solutions, it is now possible to machine even the hardest materials, such as ball bearing inserts or hardened steels (piston rods and cylinders).

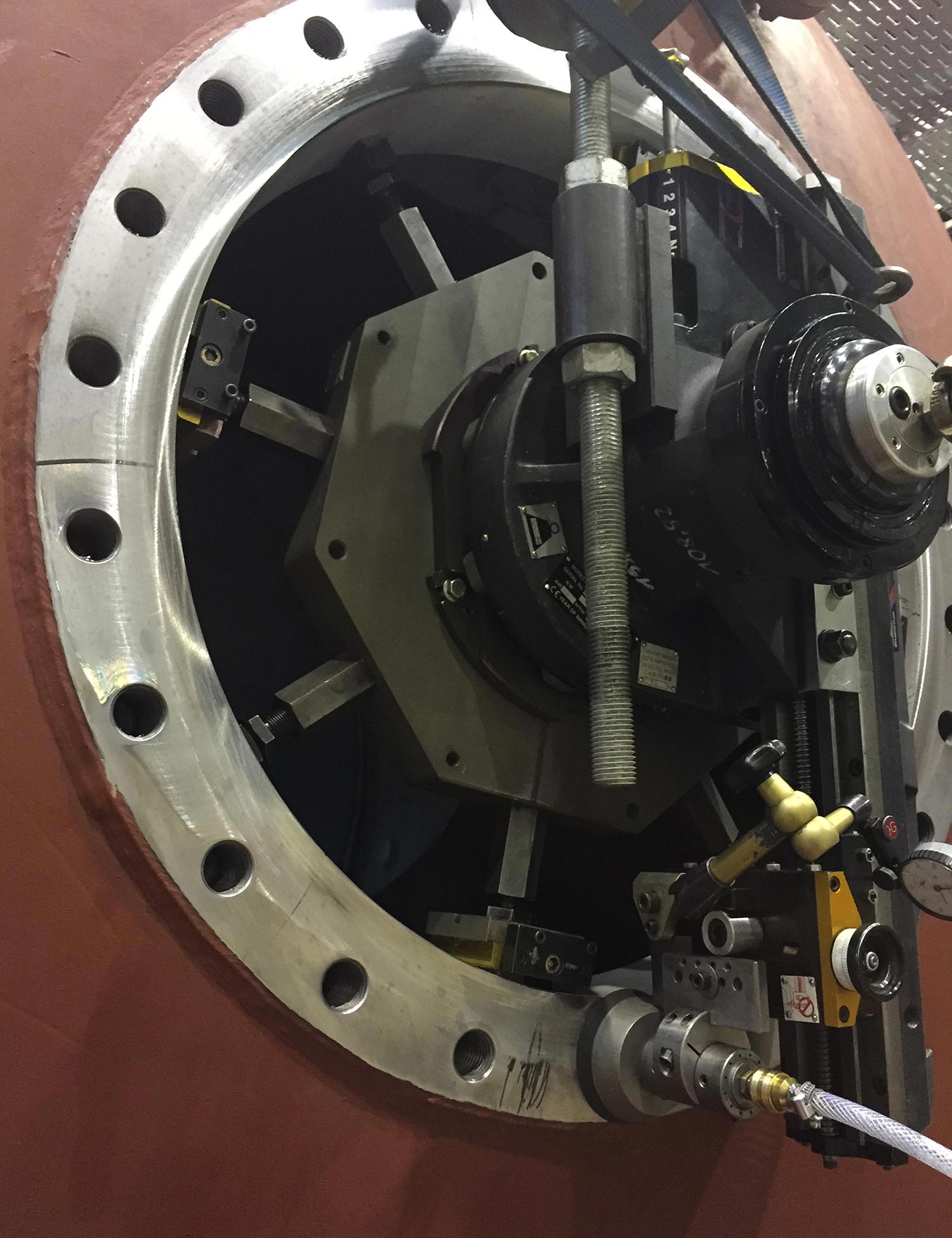

Valve seal seat grinding is our special solution if your valve seats are leaking. Very high surface quality is required for the sealing surfaces of valves in order to prevent leaks and the resulting damage. In addition, the importance of valve machining on safety-relevant valves, such as quick-acting valves in the high-pressure range on turbines, is increasing.

In addition, the machined sealing surfaces of quick-closing valves and control valves help to increase turbine efficiency.

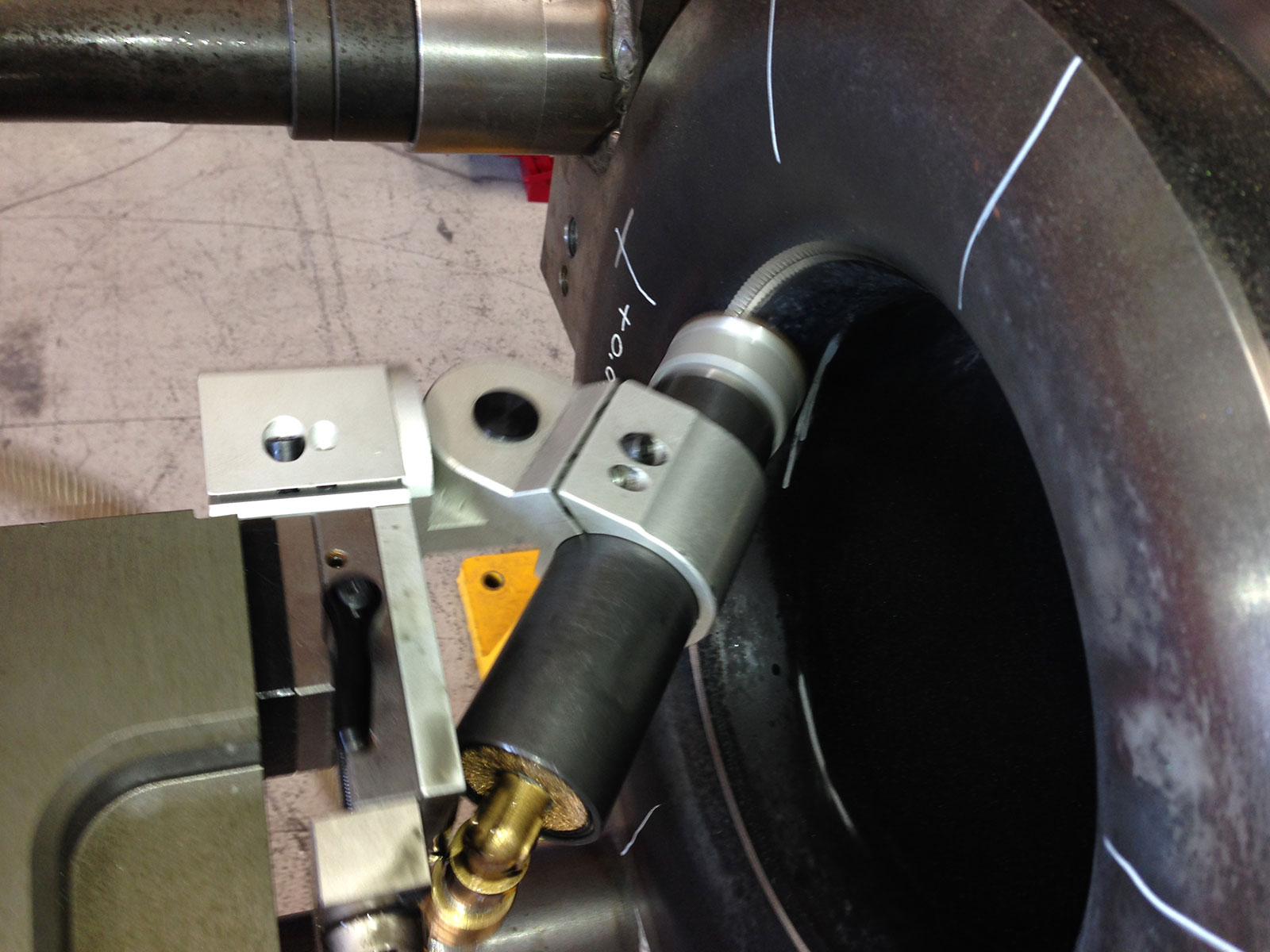

Mobile grinding with high-speed grinding machines is also used in industry, such as grinding work on cylinders of presses in the automotive industry, and on cylinders or running surfaces in the steel industry.

Grinding work plays an important role for the fine machining of plant components not only during production, but also during repairs and maintenance. The very precise process requires the highest accuracy and perfect precision. However, it is not necessary to disassemble individual components and transport them to a workshop. ARNOLD offer mobile grinding for a wide range of applications – without loss of time or transport risk and with minimal downtime.

Sealing surfaces, races, blades and other contact surfaces that no longer meet the geometric requirements, rotates and grinds ARNOLD with the help of mobile grinding equipment, so that they meet the highest demands again. Upon request, we will gladly provide you with a supporting image proof.

Finishing and precision grinding

Thanks to the many years of experience of our employees and their work with precise grinding equipment, we can provide precision machining with the utmost precision. Thanks to our expertise and our know-how, you receive workshop quality directly on site.

Even for complex shapes or difficult conditions, we develop individual solutions that allow the system to function optimally. The focus here is on the requirements on site. The goal: to grind plant components as quickly and efficiently as possible, thus avoiding failures and maintaining the profitability of the plant.

Blade grinding for the efficiency of gas turbines

In particular, turbine blades must be precisely tailored to their track. Only then can the efficiency of a gas turbine in power generation be maintained or increased. Even with the new installation highest precision is required. ARNOLD specializes in the on-site grinding of turbine blades and can perform sanding on both mobile and on-machine turbine rotors, as well as on turbine blades, using mobile sanders.

Standard solutions are not up to our standard. Our ARNOLD specialists will find the best possible grinding solution for you – for every application and directly on site.